|

Service is Our Frame of Mind

Like many entrepreneurs, Rollercoat president Joe Lancaster started out to help people he knew in business, the metal decorating business. He knew how to make better rollers faster than others and he did. Since February 1979, Rollercoat Industries has continued to offer excellent rollers for metal decorating, printing, and industrial applications.

At our modern plant in Tampa, Florida, highly trained technicians ensure each and every roller is produced and tested to the most exacting standards. Our equipment consists of CNC grinder/groovers, manual roll grinders, lathes, rubber strip builders, wet and dry autoclaves, urethane processing equipment, sandblast equipment, and presses for molded goods.

The Right Materials for the Right Job The Right Materials for the Right Job

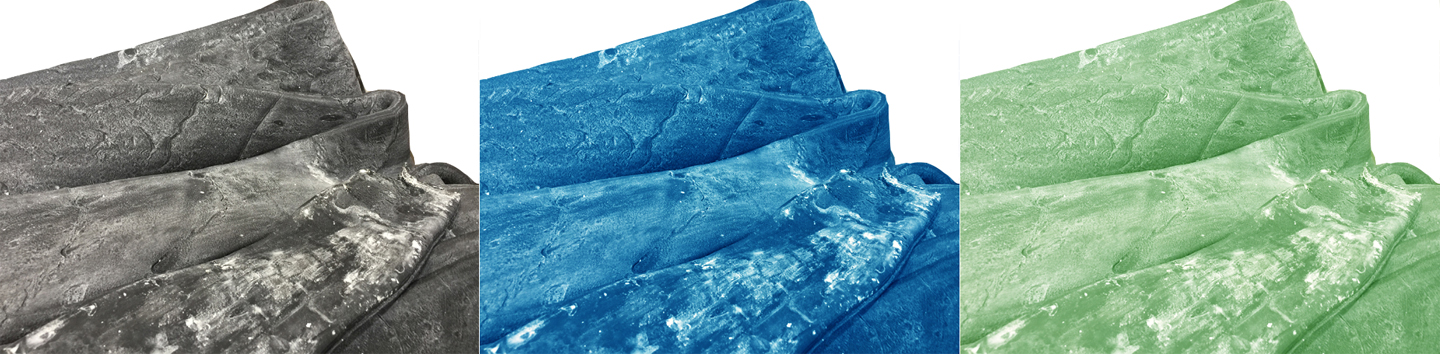

Rollercoat’s experience at choosing the right material begins with asking what application and in what environment the roller will be used. Then we can decide which material to use.

| We offer custom rollers with advanced and dependable compounds including: |

|

Silicone

Neoprene

CSPE aka Hypalon®

E.P.D.M.

Nitrile (Buna N)

Carboxylated Nitrile

Natural Rubber

SBR

Nitrile PVC

A complete line of Polyurethanes in all durometers. |

Step By Step, We Make Quality Rollers

With the latest equipment, we manufacture the best rollers. With every step, we ensure your new and recoated rollers meet the highest quality standards:

| 1. |

Each roller is carefully stripped and cores are sandblasted to ensure positive adhesion. |

| 2. |

Core and journal repairs are carried out to extend roller life. |

| 3. |

Specified rubber or polyurethane coverings are then applied, wrapped and cured using the most advanced techniques available. |

| 4. |

Rollers are individually ground with both wet and dry grinders to ensure close tolerances and surface perfection. |

| 5. |

High speed polishing and cleaning complete the process. |

|

|

|

|

|

|

|

|

|

|

Furthermore, we keep a record of each roller throughout each manufacturing level. Every roller must pass strict specifications to meet our high level of quality.

This pride, craftsmanship, and attention to detail assures excellent and economical results. Rollercoat rollers should be your choice when your job requires dependability, quality, precision, technical support, and on-time delivery. |